By strict quality control procedures.

Shareate has always put quality and customer service first.

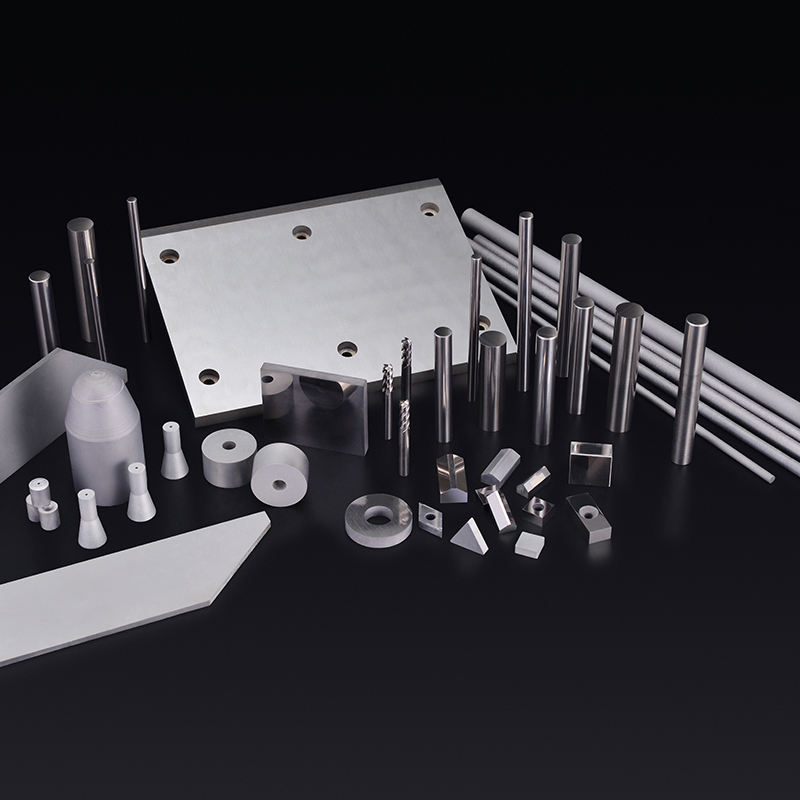

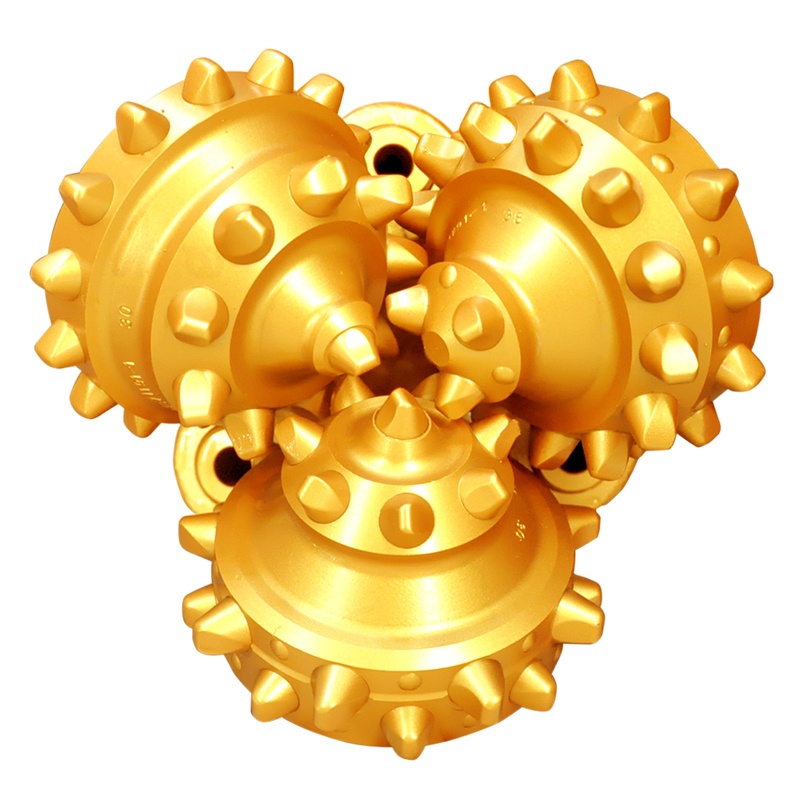

Our products include rock drilling tools, cemented carbide, etc. From the selection of raw materials to the final logistics delivery, Shareate has strict requirements. In the process of product testing, our inspectors treat products with a meticulous attitude.

1. Raw material inspection

This is the key to produce good products. Only qualified raw materials and advanced technology can produce excellent products

2. Carbon and oxygen test of mixture

Reducing the content of carbon and oxygen impurities can effectively reduce or avoid the formation of carbon and oxygen inclusions, which is conducive to improving the impact properties of cemented carbide

3. Density distribution of mixture

The particle size distribution of the mixture powder at all levels is relatively uniform, which can effectively improve the uniformity of powder filling in the process of pressing, ensure the relative uniformity of compacts density, reduce the deformation after sintering, and is conducive to the control of product forming size

4. Coercive force

Coercive force is one of the most important parameters, which can reflect the grain size and distribution of the carbide. The quality of the carbide can be improved by controlling the coercive force of the carbide.

5. Porosity

The existence and size of pores directly affect the density of cemented carbide. Due to the existence of pores, the actual density is less than the theoretical density. Cemented carbide, which is produced in the process of pressing and sintering, will reduce its density due to carburizing, under burning, fouling, bubbling, peeling, and not pressing well.

6. Microstructure

Detect microstructure features and defects. The microstructure features include phase composition, average grain size and particle size composition, thickness, and distribution of the cobalt layer. Defects include porosity, inclusion, polycrystal, inclusion, mixture, cobalt pool, carburization, decarburization, etc.

......

Shareate products will go through up to 20 steps of strict inspection before leaving the factory.

We are scrupulous about every detail, professional QC and strict checking procedure ensure our work and guarantee each piece of product which is in its best presentation.