You are here:

PRODUCT OVERVIEW

Naming of DTH Bits

| Shank | Code(with dual cylinder) | Code(with single cylinder) |

| DHD | DH | WD |

| QL | SQ | WQ |

| Mission | SM | / |

| SD | SD | / |

|

Suitable for most rock formations, most effective in the medium-hard and homogeneous rock formations. The face feature helps to reduce deviation and allows good cutting flushing on bit face. |

|

Convex face is suitable for drilling soft-medium hard rock formations under low-medium air pressure. It is deisgned for fast penetration rate in soft-medium ground formation with a good wear profile; but it has less control on hole deviation. |

|

Flat face bits are genral purpose bit suitable for drilling extremely hard and abrasive rocks formation with high air pressure. Flat face bits have good penetration rates and good erosion pattern on bit body. |

|

The drop center face design is best suited to the soft-medium hard formation, and formation with broken layers. The drop center bits have good penetration rate, and low hole deviation. |

|

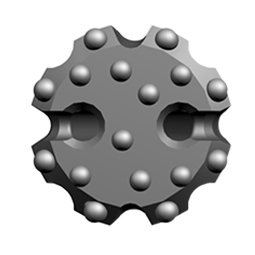

Double gauge row design is best suited for hard-very hard formation. The double gauge row configuration has good penetration and provides excellent wear resistance. |

Spherical button is the most common shape used on DTH drill bit. It provides excellent penetration in medium, hard and broken formations, suitable in most types of drilling.

Flat button is used mainly as an additional protection feature on the DTH bit. It is placed on areas where extreme wear occurs to reduce bit body wear in the area.

Ballistic button has an very aggressive profile that protrudes out farther than most of the other carbide shapes. This button has the highest penetration rate and rock breaking efficiency, and is mostly used in softer formation.

Ogive button has a higher aggressive profile that protrudes out farther than spherical button . This button has the higher penetration rateand rock breaking efficiency, and is mostly used in softer formation.

About Us

Contact Us

Phone: +86 0512 62850656

+86 0512 62851667

Fax: +86 0512-62851611

Email: info@shareate.com

Address: No.6 Weixi Road, Suzhou Industrial Park