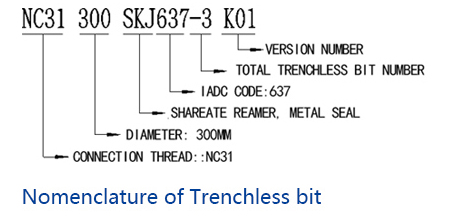

NOMENCLATURE

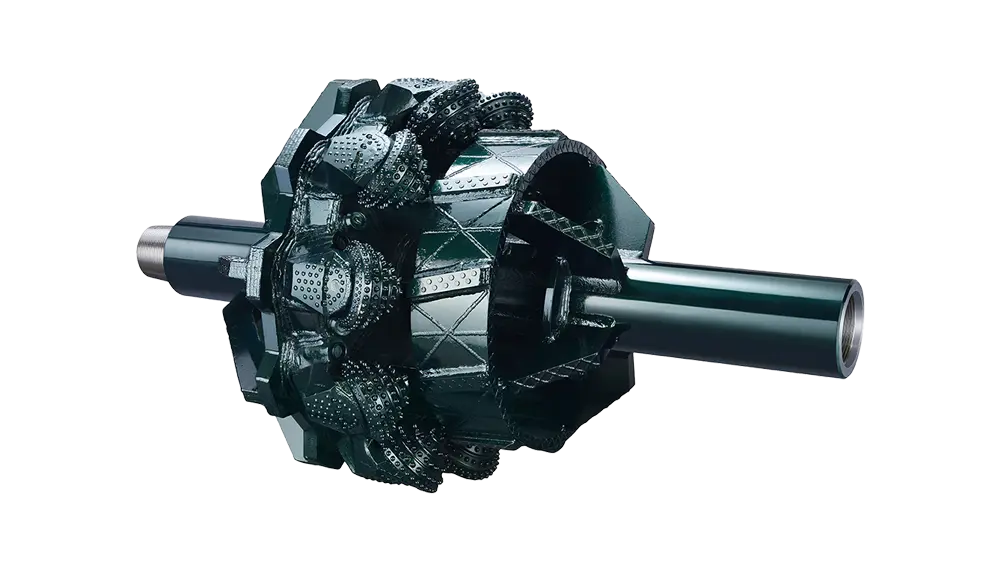

The name of the HDD rock dilling product is composed of: diameter specification, series code, IADC code, additional feature code and version number.

You are here:

The name of the HDD rock dilling product is composed of: diameter specification, series code, IADC code, additional feature code and version number.

The diameter of the tricone bit and the trenchless bits is in imperial units, such as 8 1/2”, 9 7/8” and 12 1/4”, etc. The diameter of the roller cone reamer is in metric or imperial units, like 24", 30", 300mm, 400mm, etc.

It is composed of three digits, the first digit represents the type of bit cutting structure and formation hardness, the second digit is the formation classification number, and the third digit is the bearing and sealing feature code.

It consists of three letters, which represent the classification and basic characteristics of the product. The following table 1 shows the code principle of the tricone bits and trenchless bit:

| Products | Classification code | Bearing Features | Sealing feature |

| Tricone bit | S—Universal Tricone Bits | G—Rolling bearing H—Journal bearing |

A—O-ring rubber seal V—Flat rubber seal J—Metal seal |

| C—Tricone bit for trenchless pilot hole | |||

| Trenchless bit | C |

Table 1. Code principle of tricone bits and trenchless bit

As shown in Table 2 below, it is the code principle of the reamers

| Products | Company code | Product code | Sealing feature |

| Reamer | S | K | A—O-ring rubber seal V—Flat rubber seal J—Metal seal |

Table2.Code principle of reamers

The additional feature code reflects the special structure of the products. The common additional feature codes are shown in the following table:

| Code | Additional feature |

| C | Centre nozzle port |

| G | Special enhancement of lug back |

| L | Lug back centralizing |

| T | Trimming insert |

| X | Wedge-shaped insert |

| Y | Conical insert |

It is represented by letters and numbers with specific meanings, and the numbers represent the number of improvements, among which -1, -2, -3 are added after the version number to distinguish the first, second, and third trenchless bit.

| IADC | Formation |

| 117/127 | Low compressive strength, high drill ability soft formation, such as shale, clay, salt rock, soft limestone, etc. |

| 537 | Compressive strength, medium soft, with hard abrasive inter layer, such as hard shale, anhydrite, soft limestone, sandstone, etc |

| 617 | High compressive strength, medium to hard, with thick hard inter calations, such as hard shale, limestone, dolomite, sandstone, etc. |

| 637 | High compressive strength, high abrasive and medium hard formations such as limestone, dolomite, sandstone, flint, etc. |

| Note: This table specifies the formation for common types of drill bits, and the adaptability of the drill bit and the formation should obey to the IADC principle. | |

| IADC | Pull down(KN/mm) | Recommended ROP for Rubber Seals (r/min) | Recommended ROP for Metal Seals (r/min) |

| 117/127 | 0.35~0.9 | 150~80 | 160~90 |

| 537 | 0.35~1.05 | 120~50 | 140~60 |

| 617 | 0.35~1.05 | 80~40 | 140~60 |

| 637 | 0.7~1.2 | 70~40 | 140~60 |

| note:

1) The recommended maximum pull down and rotation speed in the table cannot be used at the same time. 2) The recommended parameters in the table are the applicable drilling pressure and rotation speed of the tricone drill bit. When the trenchless bit is used on a reamer, the diameter of the reamer and the specification of the trenchless bit should be considered; 3) The larger the reamer, the lower the rotation speed of the drill pipe should be. |

|||

About Us

Contact Us

Phone: +86 0512 62850656

+86 0512 62851667

Fax: +86 0512-62851611

Email: info@shareate.com

Address: No.6 Weixi Road, Suzhou Industrial Park