Mining

SHAREATE TOOLS LTD. mining tri-cone drill bit is mainly used in large open-pit mining operations, such as open-pit coal

mine, copper mine, molybdenum mine, iron ore mine and other non-ferrous metal mine.

You are here:

Product Overview

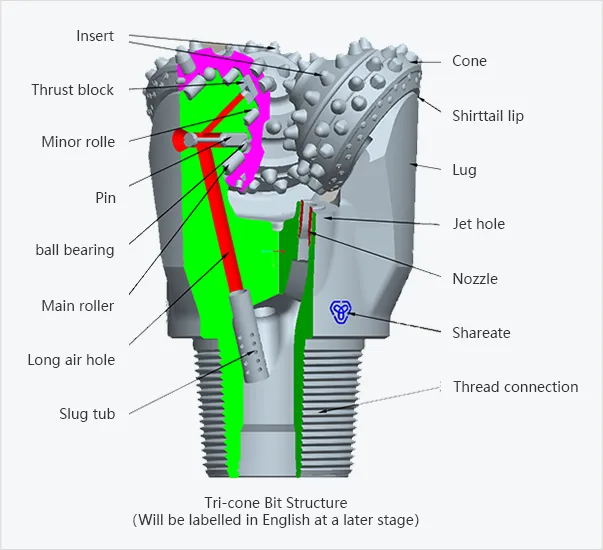

Tri-cone drill bits consists of a bearing structure, cutting structure,

shirttail and lug enhancement structures, flow channel system, and a

thread connections.

The bearing structure consists of lug bearing, cone bearing, seal ring

(sealed bearing), main rollers, minor rollers, locking bearing balls,

axle thrust plate, and recess thrust plate. It can be categorised into air

cooled open rlling bearing or sealed rolling bearing.

| Bit Structural Characteristics | SG | SGA | SGV |

| Roller bearing | ● | ● | ● |

| Open roller bearing | ● | ||

| O-ring seal | ● | ||

| Rubber flat seal | ● |

By calculating the load distribution of each component in the bearing, the bearing geometric structure is designed to distribute bearing load evenly, which enhances the working bearing life.

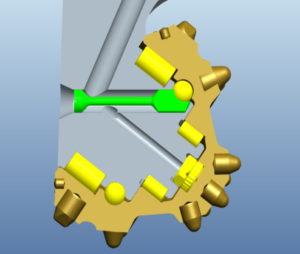

Open bearing

Bearing structure: main roller – ball bearing - minor roller - thrust block, open bearing structure without seal ring

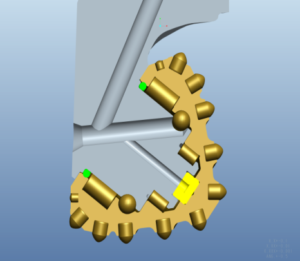

Sealed Bearing

Bearing structure: O-Ring Seal--main roller – ball bearing - minor roller - thrust block, sealed bearing

Composite Sealed Bearing

Bearing structure: Composite seal ring - main roller - ball bearing - minor roller - thrust block, sealed bearing

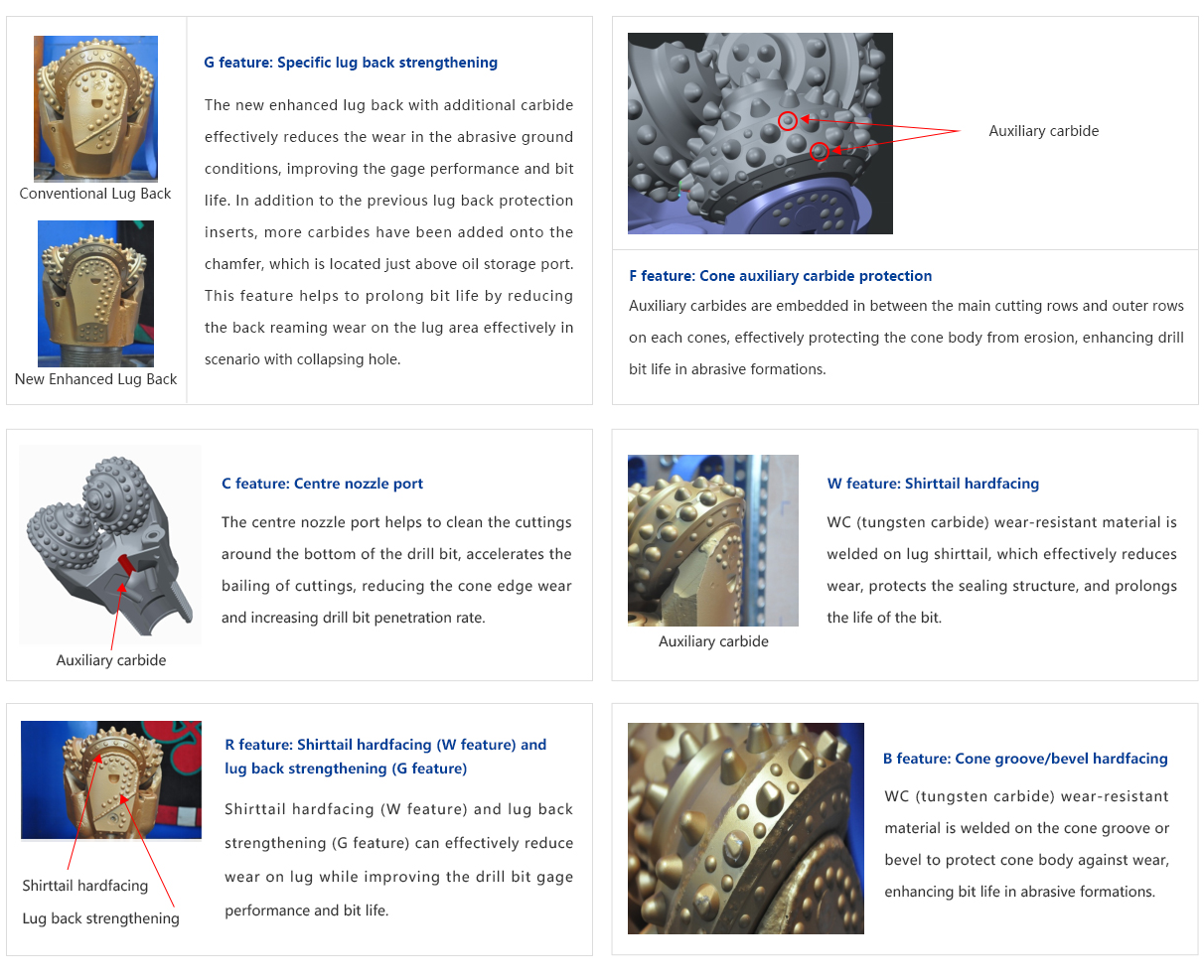

Lug Back Protection

Lug back design promoting lift force increases bailing space, accelerates bailing velocity and reduces wear on drill bit from cutting regrinds.

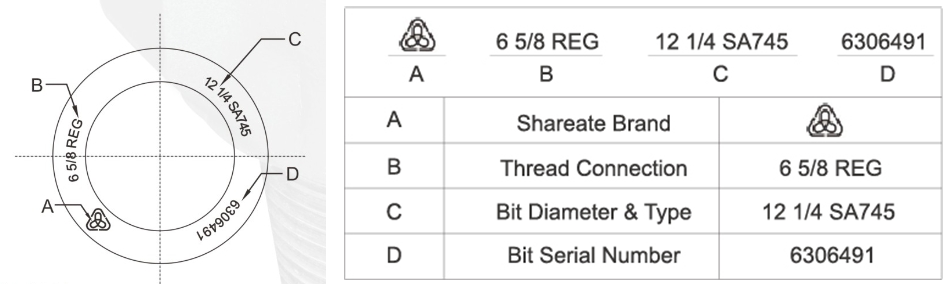

12¼ SGA 745 GF

The first part is categorised based on drill hole operation requirement for selecting the correct bit size, displayed in numbers (integer or fraction) to indicate the diameter in inches. Our current tri-cone product range includes 6 1/4, 6 3/4, 7 7/8, 8 1/2, 9, 9 7/8, 10 5/8, 11, 12 1/4, and 13 3/4 (inch).

The second part is based on drilling operating requirements for selecting the correct drill bit bearing and sealing structure, which is divided into the following series:

The third part adapts the SPE/IADC codes, consisting of three digits, with the first digit of the IADC code referencing the cutting structure and formation series, the second digit further categorises the formation classification and the last digit is the drill bit structure characteristic code.

The third digit classifies the structural characteristics of the drill bit which is divided into air-cooled bearings and sealed bearings, expressed by 2 and 5 respectively.

The fourth part affirms additional features. Shareate tri-cone drill bits can be manufactured with the following additional features:

|

Drill Bit Series |

Rock Compressive Strength(Psi) |

Rock Compressive Strength(MPa) |

|

412/415 |

4000-7000 |

27-48 |

|

422/425 |

5000-8000 |

34-55 |

|

432/435 |

6000-9000 |

41-62 |

|

442/445 |

7000-10000 |

48—69 |

|

512/515 |

9000-15000 |

62-103 |

|

522/525 |

12000-19000 |

83-131 |

|

532/535 |

15000-23000 |

103-159 |

|

542/545 |

18000-27000 |

124-186 |

|

612/615 |

23000-30000 |

159-207 |

|

622/625 |

26000-34000 |

179-234 |

|

632/635 |

29000-38000 |

200-262 |

|

642/645 |

32000-42000 |

221-290 |

|

712/715 |

37000-44000 |

255-303 |

|

722/725 |

40000-48000 |

276-331 |

|

732/735 |

43000-52000 |

296-359 |

|

742/745 |

46000-56000 |

317-386 |

|

812/815 |

49000-58000 |

338-400 |

|

822/825 |

52000-62000 |

359—427 |

| Bit Diameter | mm | 152 | 171 | 200 | 216 | 229 | 251 | 270 | 279 | 311 | 349 |

| inch | 6 1/4 | 6 3/4 | 7 7/8 | 8 1/2 | 9 | 9 7/8 | 10 5/8 | 11 | 12 1/4 | 13 3/4 | |

| API(REG) | 3 1/2 | 3 1/2 | 4 1/2 | 4 1/2 | 4 1/2 | 6 5/8 | 6 5/8 | 6 5/8 | 6 5/8 | 6 5/8 | |

| BECO | 4 1/2 | 4 1/2 | 4 1/2 | 6 | 6 | 6 | 6 | 6 | |||

Note: We can design and manufacture custom size and specification connection thread according to customer's requirements.

| Bit Size | API REG Thread | Make-up Torque | |

| Inch | Millimetre | Inch | kN/m |

| 6 1/4 | 158.8 | 3 1/2 | 9.5~12.2 |

| 6 3/4 | 171.5 | 3 1/2 | 9.5~12.2 |

| 7 7/8 | 200.0 | 4 1/2 | 16.3~21.7 |

| 8 1/2 | 215.9 | 4 1/2 | 16.3~21.7 |

| 9 | 228.6 | 4 1/2 | 16.3~21.7 |

| 9 7/8 | 250.8 | 6 5/8 | 38~43.4 |

| 10 5/8 | 269.9 | 6 5/8 | 38~43.4 |

| 11 | 279.4 | 6 5/8 | 38~43.4 |

| 12 1/4 | 311.2 | 6 5/8 | 38~43.4 |

| 13 3/4 | 349.3 | 6 5/8 | 38~43.4 |

| IADC | Weight on Bit per Inch of Bit Diameter

(lb/in) |

Rotary Speed (r/min) | Cutting Structure | Applications |

|

412 415 |

1000—2000 | 90—120 | Conical on gage and inner rows | Designed for very soft formations with low compressive strength and high friability such as shale, soft limestone, sandstone, gravel clay, soft dolomite, coal. |

|

432 435 |

1000—4000 | 90—120 | Conical/Chisel on gage, Conical inner rows | Designed for very soft formations with low compressive strength and high friability such as shale, soft limestone, sandstone, gravel clay, soft dolomite, coal. |

|

532 535 |

2000—5000 | 80—110 | Conical/Chisel on gage, Conical inner rows | Designed for soft formations with low compressive strength, such as shale, soft limestone, interbedded dolomite, coal. |

|

612 615 |

3000—5000 | 60—100 | Conical/Spherical on gage, Conical inner rows | Designed for high compressive strength, medium hard and abrasive formations, such as limestone, sandstone, interbedded dolomite. |

|

632 635 |

3000—6000 | 60—100 | Conical/Spherical on gage, Conical inner rows | Designed for high compressive strength, medium hard and abrasive formations, such as limestone, sandstone, interbedded dolomite. |

|

732 735 |

4000—7000 | 60—90 | Spherical on gage, Conical/Double spherical on inner rows | Designed for high compressive strength, hard and abrasive formations, such as granite, limestone, sandstone, dolomite. |

|

832 835 |

5000—8000 | 50—80 | Spherical on gage, Double spherical on inner rows | Designed for high compressive strength, hard and abrasive formations, such as magnetite quartzite, quartzite, granite. |

Note: Maximum weight on bit and rotation speeds should not be applied at the same time.

The common failure types for tri-cone bits are bearing failure, cutting structure failure, and cone body wear.

| Failure types | Failure image | Recommendation | Image |

| Bearing failure |  |

Recommend sealed bearing |  |

| Broken Insert (Cutting rows) |  |

Select a bit suitable for harder formation |  |

| Broken Insert (Gage rows) |  |

Choose the feature F for drilling in soft formation to reduce cone body wear |  |

| Broken Insert(Coring) |  |

Choose the feature F for drilling in hard formation to reduce cone body wear |  |

| Shirttail and lug back wear |  |

Choose the feature R for strengthened shirttail and lug back protection |  |

| Wear on the top of lug back |  |

Choose the feature R with protection on the top of lug back |  |

About Us

Contact Us

Phone: +86 0512 62850656

+86 0512 62851667

Fax: +86 0512-62851611

Email: info@shareate.com

Address: No.6 Weixi Road, Suzhou Industrial Park