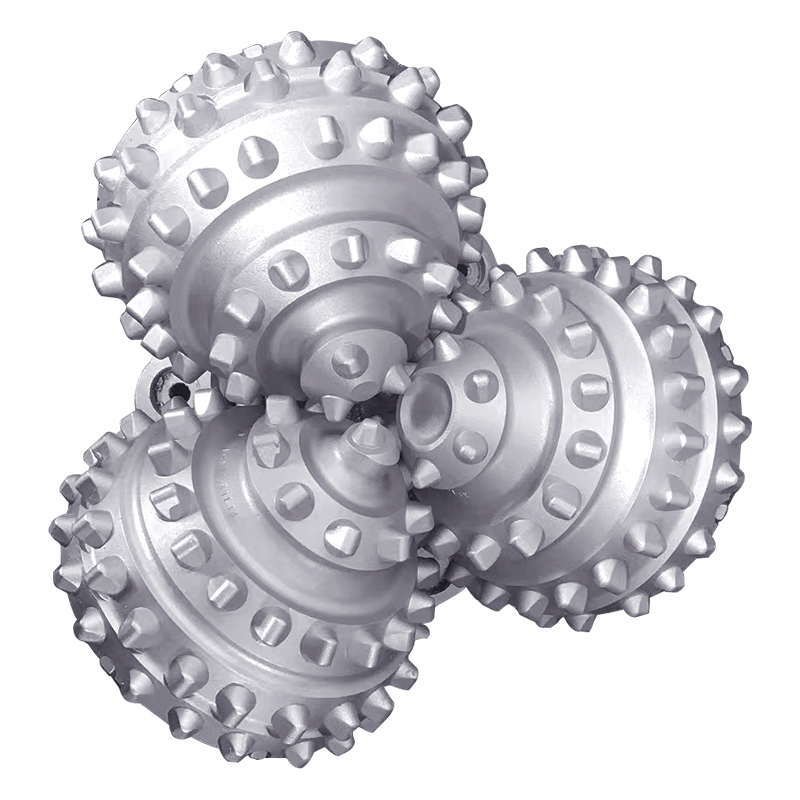

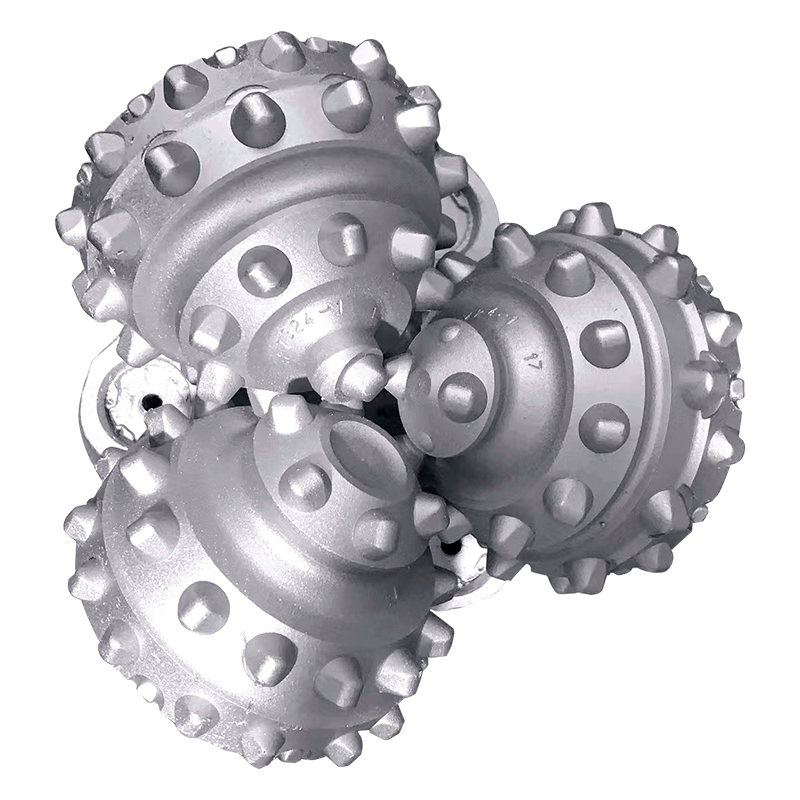

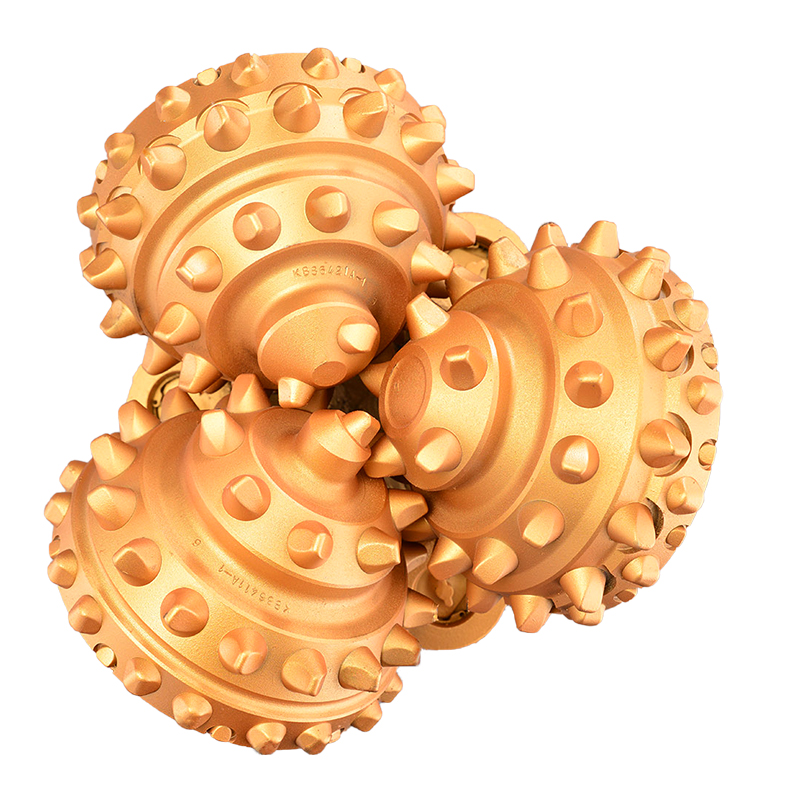

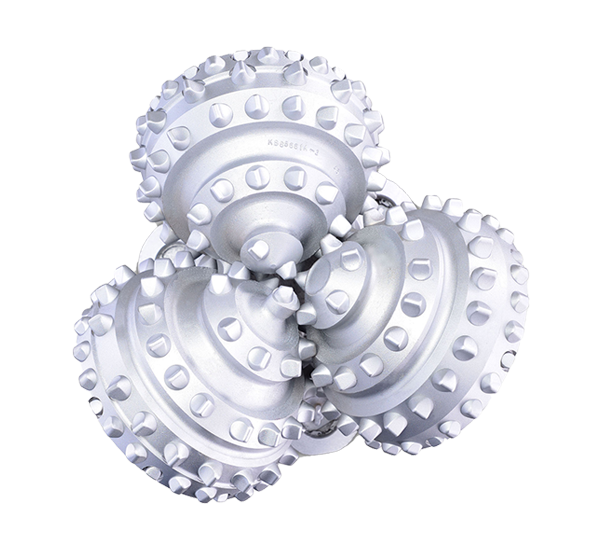

MAIN FEATURES

Unique bearing design makes the structure more stable, superior in

performance and strong in adaptability.

Adopt high temperature resistant and wear resistant rubber sealing

structure to prolong service life.

Precisely designed cutting structure is suitable for formations of

different hardness and lithology.

Excellent oil storage system balances the pressure difference between

the inside and outside of the bearing, extending the life and stability of

drill bit.

Diverse bit strengthening features can solve different types of

problems in dilling

process.